plasmotion GmbH has started the transfer of the multi-nozzle JETPEP technology from TU Freiberg and is being funded by the Sächsische Aufbaubank (SAB) as part of the "EFRE/JTF - Technology Transfer Funding 2021 to 2027" program. As part of the program, all property rights and the necessary adaptation developments for the market launch of the technology will be transferred.

Project description and objectives

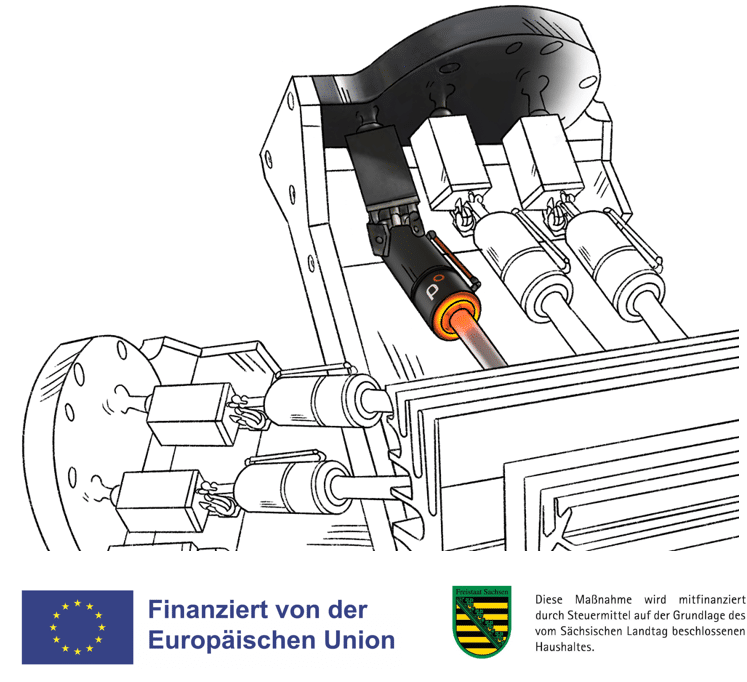

The finishing of metal surfaces (polishing, deburring, cleaning, sterilizing) is an omnipresent challenge, with industrial customers demanding ever higher quality and ever greater flexibility. This often leaves only one solution: manual polishing or deburring, often outsourced to Eastern Europe. JETPEP - jet plasma polishing - offers an alternative for the first time. Thanks to the unique combination of electrochemistry and plasma physics, plasma polishing enables very uniform, true-to-shape polishing - especially on complex workpieces. JETPEP opens up this highly efficient and environmentally friendly process for surface-precise machining. The previous approach, realized by plasmotion GmbH (Technologienehmer), of using a nozzle to process the surface at the decisive points by means of movement, is well suited for applications in the field of plant engineering and toolmaking.

However, the true economic potential can only be realized through the parallel use of several electrolyte nozzles that process the workpiece, e.g. in continuous flow systems (multi-nozzle JETPEP). The approach of allowing nozzles with different jet shapes, jet directions or other parameters to act simultaneously on the workpiece has been developed at the TU Bergakademie Freiberg (technology provider) and a patent has been applied for. It is supplemented and can be implemented industrially by the innovative addition of parameterized condition monitoring of plasma polishing electrolytes. The TU Freiberg has filed an invention disclosure for this. Both innovations are to be transferred to plasmotion GmbH and qualified through adaptation development.

Results:

The project is still ongoing.